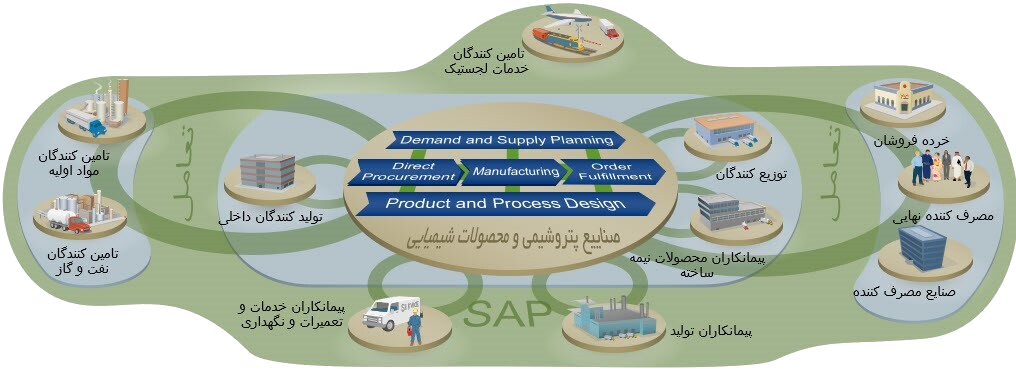

صنایع پتروشیمی و محصولات شیمیایی

هوشمندسازی صنایع تولیدی حوزه پتروشیمی و محصولات شیمیایی

فرآیندهای اصلی زنجیره ارزش صنایع پتروشیمی :

-

مدیریت نوآوری (تحقیق و توسعه محصول)

Innovation Management in the chemical industry is the systematic approach to investigate for new as well as enhanced products and processes in order to meet market and demand requirements, improve the product portfolio, and gain competitive advantage. R&D activities are either initiated by analyzing market opportunities or systematic screening of chemical substances and processes. These activities include definition of requirements, development and testing of product concepts, full definition and development of products and processes, sourcing for suppliers involved, planning the manufacturing and supply chain, preparation of marketing programs, and successful launch of the new products. On top of that it is about defining the overall product strategy, managing the entire product program and monitoring all the projects and activities in order to streamline all R&D related issues.The SAP solution for Innovation Management consists of two major parts:1. Product Development covers the process of defining the product, gathering requirements, developing the product, sourcing for suppliers involved and managing the ramp-up.2. R&D Management covers strategic project portfolio management, idea management and operational project management. It enables companies responsible to manage schedules, resources, assigned documents and materials, costs, and budgets. -

مدیریت تأمین کنندگان (منبع یابی و مدیریت تأمین)

Chemical manufacturers need to reduce the cost of procurement and the time for inventory replenishment. In order to achieve this they require a more strategic approach to sourcing and vendor management. In this context, comprehensive performance tracking becomes critical, in order to be able to analyse the extent, that the sourcing goals are being met and to provide visibility into global spend and supply base data.

Chemical manufactures are in a much better position to negotiate contract terms and control procurement costs, if they are able to analyse and really understand the abilities and restrictions of their suppliers. The right key performance indicators need to be selected and tracked, so that chemical companies are enabled to immediately see if "leakage" is diminishing the efficiency of strategic sourcing efforts, if shifts in allocation to preferred vendoers make sence, or perform vendor improvement measurements.

Once the strategy is determined, SAP helps improve the efficiency of execution with functions that enable management by exception. Customizable alerts call the attention to potentially problematic issues or incidents, like e.g. approaching contract expiration dates and insufficient supplier performance.

-

برنامه ریزی و عملیات زنجیره تأمین (مدیریت موجودی و انبار و برنامه ریزی زنجیره تأمین)

Chemical manufacturers need to reduce the cost of procurement and the time for inventory replenishment. In order to achieve this they require a more strategic approach to sourcing and vendor management. In this context, comprehensive performance tracking becomes critical, in order to be able to analyse the extent, that the sourcing goals are being met and to provide visibility into global spend and supply base data.

Chemical manufactures are in a much better position to negotiate contract terms and control procurement costs, if they are able to analyse and really understand the abilities and restrictions of their suppliers. The right key performance indicators need to be selected and tracked, so that chemical companies are enabled to immediately see if "leakage" is diminishing the efficiency of strategic sourcing efforts, if shifts in allocation to preferred vendoers make sence, or perform vendor improvement measurements.

Once the strategy is determined, SAP helps improve the efficiency of execution with functions that enable management by exception. Customizable alerts call the attention to potentially problematic issues or incidents, like e.g. approaching contract expiration dates and insufficient supplier performance.

-

مدیریت عملیات (برنامه ریزی تولید، تولید، مدیریت دارایی های سازمان)

To be successful in today´s increasingly time-sensitive and competitive markets, chemical producers need manufacturing processes that are fast, flexible, and adapt quickly to change. Achieving this objective requires integrated solutions that connect supply chains to plant processes, production equipment, and process control systems in a seamless, customer-centric network.

SAP provides the only integrated solution that enables both bulk and specialty chemicals manufacturers to integrate all components of manufacturing management within an e-business platform. By covering all aspects of chemical manufacturing, SAP solutions can be implemented in an incremental, process-driven fashion. Also, an integrated enterprise-wide laboratory information management system (LIMS) closes the gap between production and the laboratory, providing consistent, up-to-date information to all relevant partners.

-

فروش و بازاریابی

Chemical manufacturers sell chemical products and services to an extremely diverse customer base, a business that is becoming more complex day by day.Building customer loyalty and value in this environment requires Sales & Marketing systems that are attuned to the requirements of individual marketing, sales, service and customer support groups.Up-to-date information on customers, revenue and sales channel performance on a detailed level is required by sales managers, whereas product managers need quick access to relevant market and customer information when responding to changes in demand or upcoming opportunities. Equiped with this type of data and a consistent customer and market view, decision-makers can focus resources on the most profitable business.Account-relevant information helps the sales force to effectively and efficiently prepare every type of sales call and work on opportunities, either perfomed by mobile sales or customer interaction center. The full set of selling capabilities is completed by an industry-specific e-commerce functionality.Chemical companies rely on their order management systems to provide real time and accurate availability and delivery dates, and the flexibility and ability to react to market opportunities with optimized capacity allocation. This ensures the most critical and profitable orders and customers are supported. Chemicals-specific features like batch management or product-relevant information (e.g. Material Safety Data Sheet (MSDS), Technical Data Sheet (TDS), or Certificate of Analysis) may be included.In today´s global environment with it´s complex supply and transportation network across numerous country boundaries, a solution that delivers integration of customer demand and market supply and includes comprehensive foreign trade capabilities can help minimize internal distribution costs as well as as the cost of delays of orders to customers. -

مدیریت کیفیت و ریسک

Quality Management in the chemical industry is no longer simply about integrating internal business processes. The focus has shifted to the employees and their dedication and skills, while efficient business processes remain critical factors for success. The fast, direct exchange of internal and external information and a global information flow are essential for staying ahead of the competition.

The QM solution enables chemical companies to manage and assure product quality, monitor and improve quality standards and document quality compliance for subsequent audits.

The Compliance solution offers a wide range of functionalities to fulfill legislative requirements in certain areas like environment, health & safety and global trade processing.SAP solutions for Governance, Risk and Compliance support an integrated, end-to-end strategy to help you achieve greater transparency and predictability, streamlining GRC processes and, ultimately, improve overall enterprise performance. Our solutions address Environment, Health & Safety, Business Process Controls, Governance, Risk Management, Global Trade Services, Access and Authorization Controls (formerly known as Virsa).